Boston Micro Fabrication (BMF), a pioneer in cutting-edge manufacturing solutions tailored for ultra-precise applications, has unveiled its foray into the domain of dentistry with the introduction of UltraThineer™, an innovation that claims the distinction of being the world’s thinnest cosmetic dental veneer. This avant-garde collection of 3D-printed veneers harnesses the power of projection micro stereolithography (PµSL), a revolutionary technique crafting veneers that outshine their conventional counterparts in terms of slenderness by a factor of three, while simultaneously demanding notably less preparatory effort from dental practitioners. Consequently, this innovation not only preserves the enamel of patients but also reduces the preparation process. The impending availability of UltraThineer veneers in the United States is anticipated in the spring of 2024, contingent upon assessment by the U.S. Food and Drug Administration (FDA).

“The technology underpinning these 3D-printed zirconia veneers is astonishingly thin yet robust, promising swift and painless fortification and safeguarding of tooth surfaces. It effectively wards off the effects of cold acid stimulus and wear, while substantially enhancing aesthetics. Remarkably, this innovation obviates the need for conventional ceramic veneer methodologies, obliterating the entire tooth reduction phase.”

BMF remains steadfast in its commitment to conceive applications where its distinct micro-scale, precision-driven printing technology can meaningfully truncate production timelines and costs, fostering an environment conducive to innovation. The collaborative effort between BMF and Peking University has birthed UltraThineer veneers, characterized by state-of-the-art materials, a streamlined production workflow, and an impeccably refined finishing process, culminating in veneers that are not only slender and comfortable but also less intrusive. Additive manufacturing, more commonly known as 3D printing, has already left an indelible mark across myriad dental applications, including orthodontic aligners, mouthguards, drill guides, and dentures. The driving force behind this adoption is the imperious demand for personalized and bespoke solutions that can be produced on-demand.

“The capability to fabricate ceramics with such minimal thickness has the potential to be a watershed moment. Our current methodologies for producing veneers with minimal preparation can be labor-intensive in contrast to the milling of all-encompassing zirconia crowns. Preserving the patient’s enamel through judicious reduction is a principle that should be upheld whenever feasible. The advent of this new technology, facilitating the creation of intricate, ultra-thin veneers, is an eagerly anticipated milestone. BMF’s tireless pursuit of advancement and innovation continues to expand the frontiers of dentistry, serving as a wellspring of inspiration on a global scale,” remarked Jessica Love, representing Capture Dental Arts, a preeminent provider of cosmetic dental services in the United States.

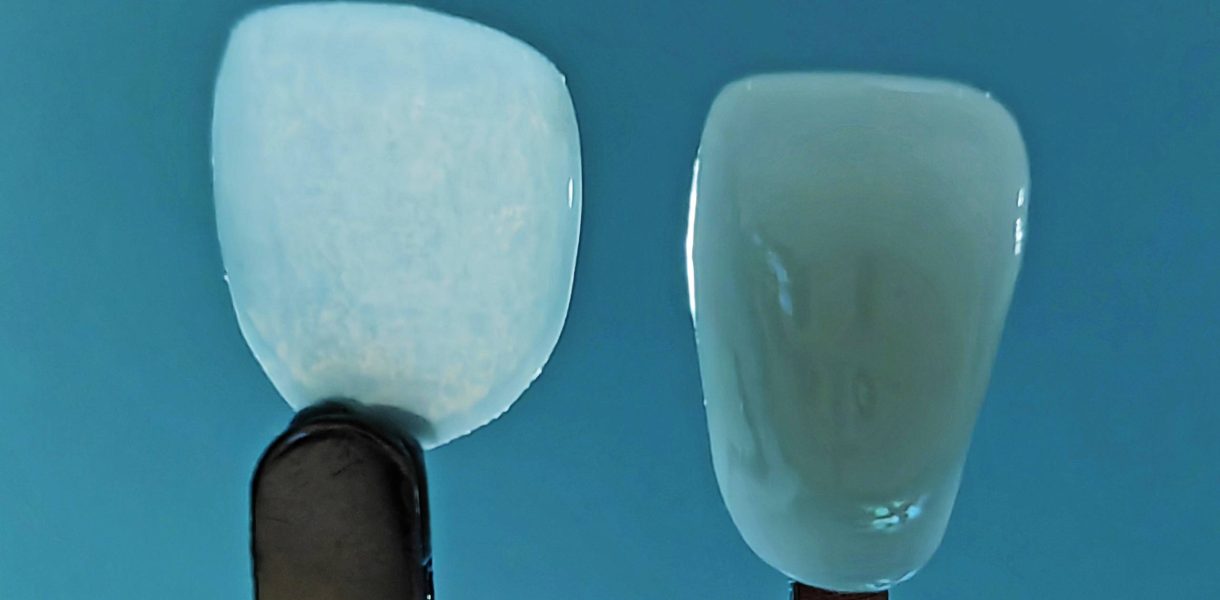

In the present scenario, veneers materialize at a thickness of approximately 0.5 mm or more, necessitating substantial preparatory work on existing teeth. This procedure, marked by its invasiveness, irreversibility, and patient discomfort, stands in stark contrast to the promise of ultra-thin veneers. The latter obviates the need for extensive tooth preparation, preserving as much enamel as feasible, with each veneer measuring a mere 100 µm in thickness. The array of ultra-thin zirconia veneers offers dentists the freedom to realign, reshape, or brighten teeth through a process that is facile, painless, and minimally intrusive.

“The technology propelling these 3D-printed zirconia veneers, distinguished by their thinness and strength, holds the capacity to swiftly and effortlessly reinforce and safeguard tooth surfaces. It is efficacious in countering the impact of cold acid stimulation and erosion, culminating in a substantial enhancement of aesthetics. Of greater significance, it circumvents the traditional ceramic veneer approach, effectively nullifying the need for tooth reduction,” articulated Professor Sun Yuchun from Peking University School of Stomatology.

In tandem with furnishing machinery, materials, and software to industries aspiring to fabricate high-precision components, BMF has embarked on a trajectory of developing and nurturing applications that find their essence in the PµSL process.

“By harnessing our unparalleled technology, companies spanning diverse sectors, from electronics to medical devices, are successfully keeping pace with the escalating trend of technological miniaturization. Beyond our collaborative endeavors in fostering innovation with our clientele, we are thrilled to unveil one of the premier instances of self-conceived application of our technology,” affirmed John Kawola, CEO-Global of BMF. “We are cognizant of the prospective benefits that thinner veneers can offer both patients and dentists alike, and eagerly anticipate the infusion of heightened precision into the realm of cosmetic dentistry.”